Matrix Metrology: Our Capabilities Exceed the Boundaries of Space!

Comprehensive service is our goal

Dimensional Inspection

Reverse Engineering

3D Laser Scanning

Tool, Jig, and Fixture Building, Verification, & Certification

CAD to Part Inspection and Analysis

Bearing/Bore Alignment

Fabrication/Assembly

Complex Pipe Fitting and Cutting

In-process Inspection

Field Machining

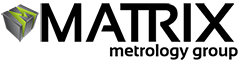

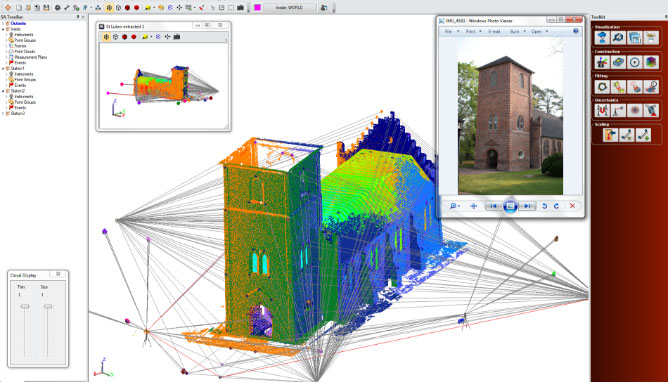

Spatial Analyzer—the Premier Metrology Software

SA is a highly flexible, instrument-independent, traceable 3D graphical software platform that makes it easy for users to: inspect parts, build, analyze data, report, reverse design.

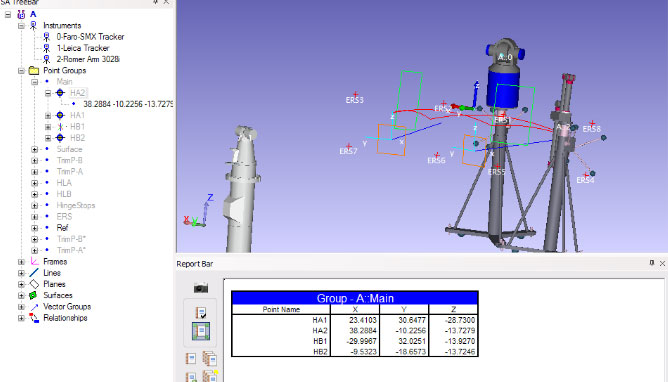

Generated CAD models can demonstrate a high degree of accuracy in functional relationships between parts.

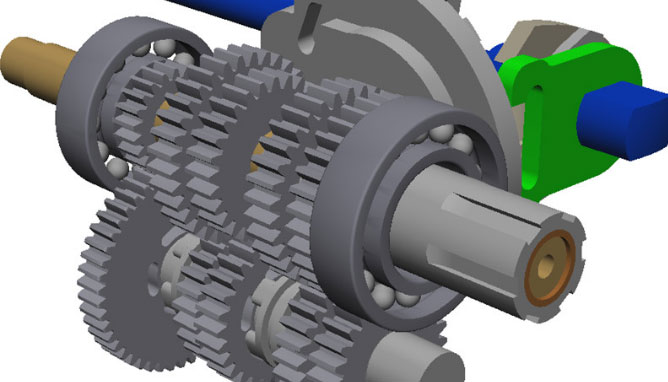

Part inspection using programmed GD&T for instant pass/fail data.

Laser scanning of historic building using scanner and tracker in unison.

In process view as a functional CAD model of this helicopter is built.